Anti-reflective glass

Day and night, our specially coated anti-reflection glass ensures, in façades as well as indoors, particularly clear views both from inside and outside.

The reflection-free laminated glass for art and product presentations

LUXAR CLASSIC is an anti-reflective, anti-glare white glass with a residual reflection of less than 1% and laminated with a special film for UV and splinter protection.

LUXAR CLASSIC is used to present exhibits in museums and exhibitions. It ensures an unadulterated colour experience and direct, reflection-free transparency. As a laminated glass, LUXAR CLASSIC also offers UV protection and resistance to mechanical attacks, with the splinter binding also minimising damage in the event of breakage.

Aesthetics Completely invisible; clear transparency

Functionality Minimum residual reflection of less than 1%; as laminated glass with UV protection from up to 99% as well as splinter protection

Usage For picture frame glazing and display case glass in museums and exhibitions

The non-reflective glass for a clear view in windows and façades

Non-reflective glass LUXAR® allows a direct view of reality – whether at a shop counter, in front of the shop window, etc. The anti-reflective coating LUXAR® is characterised by a high level of durability and abrasion resistance and can be processed into both safety glass and insulating glass.

LUXAR® ensures an unadulterated colour experience and a reflection-free view up to a viewing angle of 45°. Coating with LUXAR® insulating glass adds a special touch: on the one hand, improved light transmission while on the other, improved U and g values in combination with SILVERSTAR thermal and solar protection coatings.

Aesthetics Almost invisible glass thanks to minimal reflection

Functionality Clear view; unadulterated color experience; improved light transmission

Usage Refined basic glass for processing into safety or insulating glass

Technical specifications

|

LUXAR® |

LUXAR® F |

|

|---|---|---|

|

Size |

1900x3210mm |

9000x3210mm |

|

Thickness |

2 – 12 mm |

4 - 15 mm |

|

One side coated |

Reflection: 4.5 % |

Reflection: 4.8 % |

|

Both sides coated |

Reflection: < 0.5 % |

LUXAR® F only one side coated available |

|

Laminated glass |

Reflection: < 0.5 % |

Reflection: 1.2 % |

|

Tempered/Heat strengthened glass |

possible |

possible |

Downloads

The glass for a non-reflective view

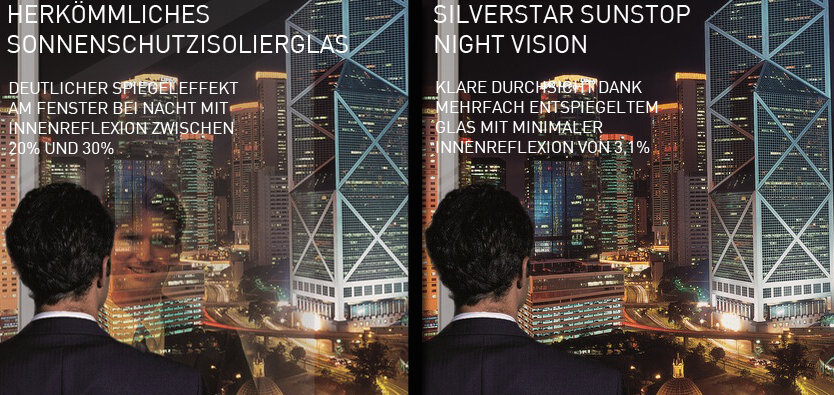

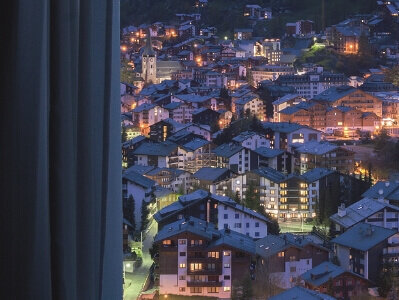

Thanks to minimal internal reflection, SILVERSTAR SUNSTOP Night Vision ensures a reflection-free view of the outside – particularly in the dark.

The insulating glass also offers a brilliant exterior view and all the advantages of an efficient solar protection glass.

Process Thanks to special coating, internal reflection is reduced to a minimum 4%

Function Non-reflecting view; very good summer heat protection during the day

Usage For houses, hotels or restaurants with spectacular views

Technical specifications

|

Products |

Light transmission level (%) |

Degree of light reflection ext. (%) |

Degree of light reflection int. (%) |

Colour rendering index |

Energy absorption (%) |

Solar Factor g EN (%) |

colour |

|

SILVERSTAR NIGHT VISION T |

32 |

35 |

7 |

94 |

51 |

26 |

silver blue |